NewAir I.B. Express 氣墊緩衝包裝

Roll Winder accessory sold separately.

The Versatile, Inflatable Cushioning System for Any Packaging Operation

Tiny Footprint, Enormous Production

The NewAir I.B.® Express inflatable cushioning system from Sealed Air quickly produces inflatable cushioning, in 12" and 24" film widths, at speeds up to 55 linear feet per minute — fast enough to keep up with the most demanding packaging operations. The small footprint and variety of batching, delivery and converting options make the NewAir I.B.® Express system the perfect fit in almost any packaging environment.

The Right Material for your Application

With the NewAir I.B.® Express system, you can customize the cushioning output. Choose between two different film widths, 12" and 24", and a variety of regular and premium film strength options.

Save Valuable Floor Space

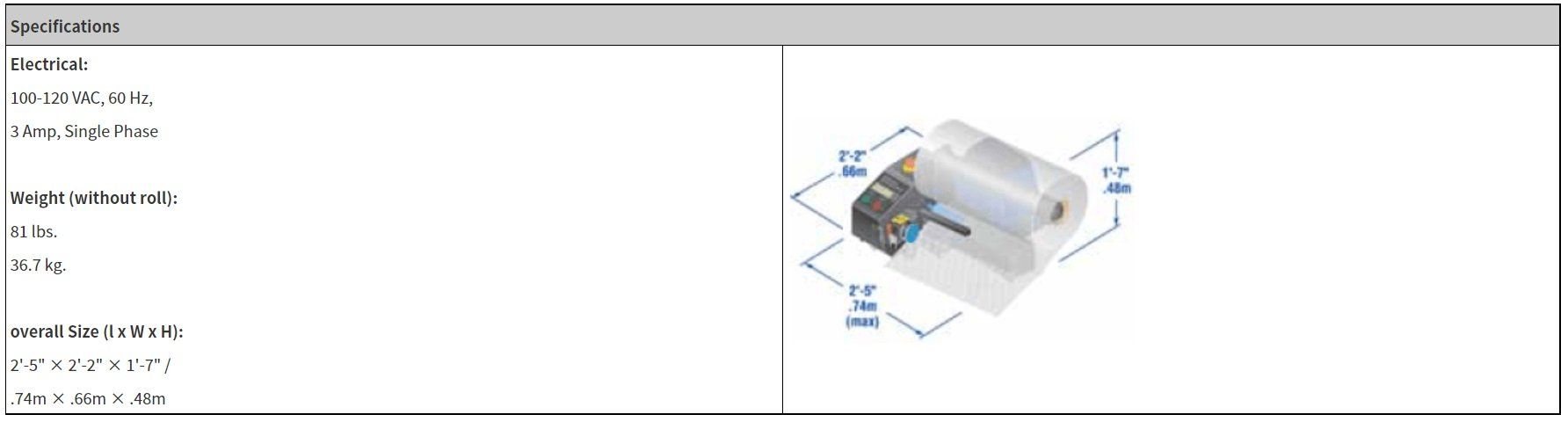

The NewAir I.B.® Express has a compact footprint (less than 6 sq. ft.) that works well in cellular packaging environments. The compact design fits comfortably on a tabletop, or can be mounted on a table-side stand. A single film roll can equal 5,000 square feet of ½ inch Barrier Bubble® material, creating on-demand packaging that saves storage space and handling.

System Accessories For Every Configuration

The NewAir I.B.® Express is supported by a large array of system accessories, making it flexible enough to be used in any and every packaging operation.

SYSTEM STAND AND ROLL WINDER

With the optional Roll Winder attachment, the NewAir I.B.® Express system can create a 36" roll of material in under three minutes, for decentralized packaging environments.

INSTASHEETERr™ CONVERTING SYSTEM

At the touch of a footswitch, the Instasheeter™ Converting System cuts custom sheets of NewAir I.B.® material that provide excellent cushioning or blocking and bracing.

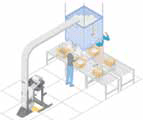

JETSTREAM™ DELIVERY SYSTEM

The JetStream Overhead Delivery System allows one NewAir I.B.® Express system to feed packaging stations, using a patented air-driven process. Ideal for high-volume, high-throughput environments

FOOT PEDAL

An optional foot pedal allows the operator to easily control the flow of material.