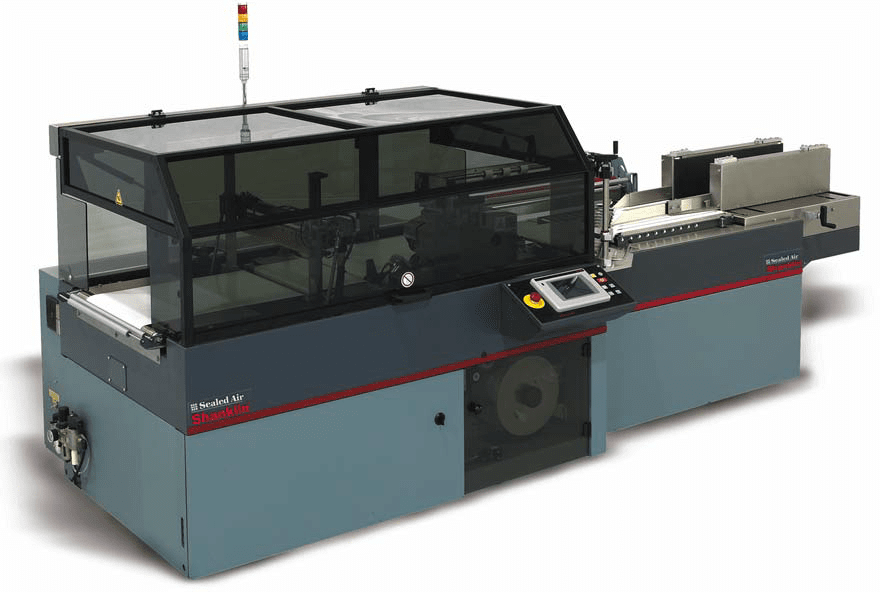

Shanklin Omni 封口機

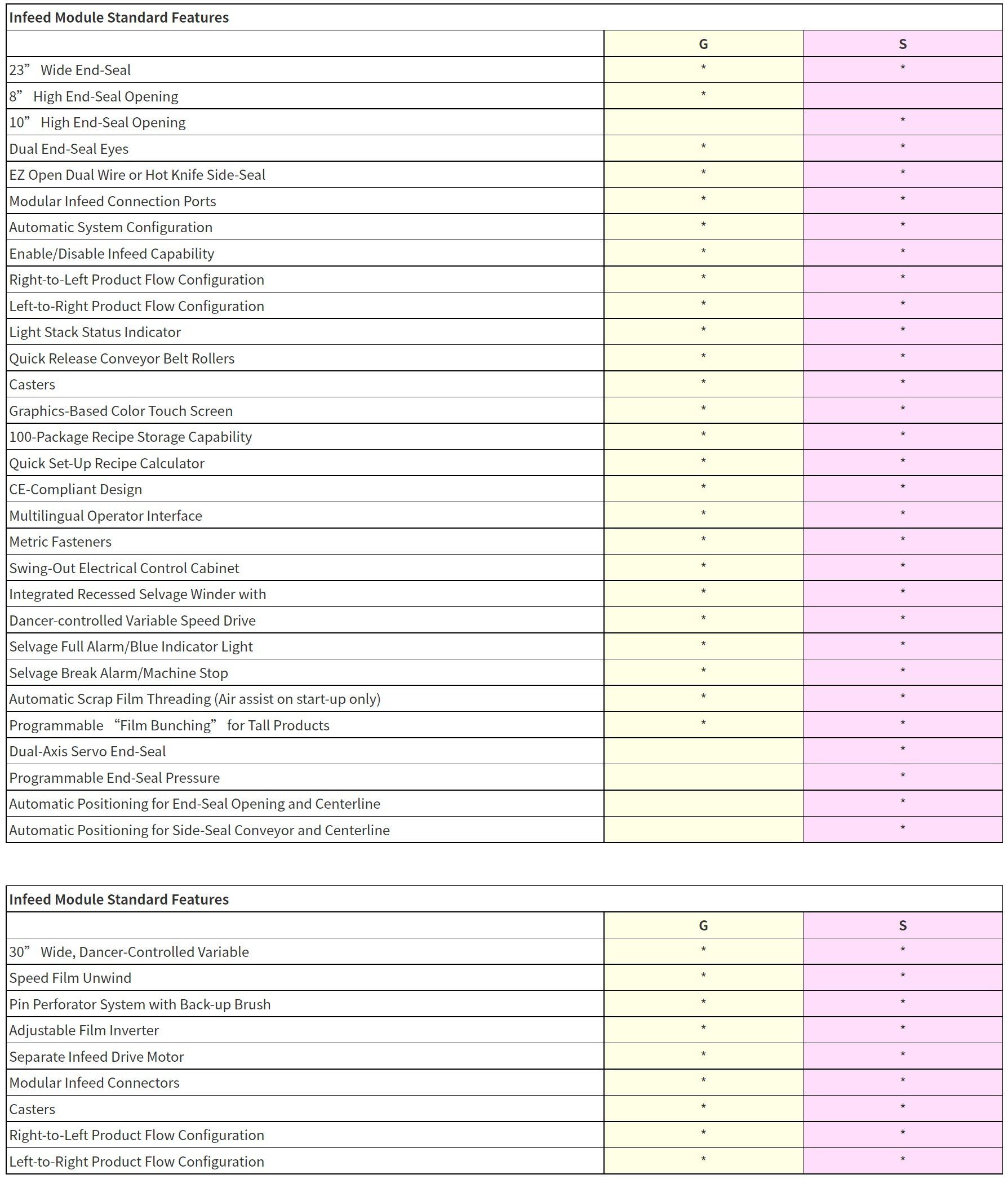

Servo Motion-Control

Technology - Omni S

• Fast - High packaging speeds

• Programmable – Adjustable end-seal pressure, film bunching for tall products, automatic positioning for end-seal opening, end-seal centerline, side-seal conveyor positioning and side-seal centerline

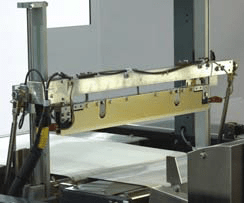

Versatile Sealing System

• Large capacity - The wide and high end-seal opening allows plenty of room to package large, tall products

• Selection - Choose either EZ

Open dual wire or hot knife sideseal assembly, and SmartWire® or hot knife end-seal assembly

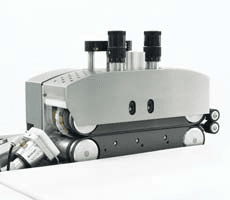

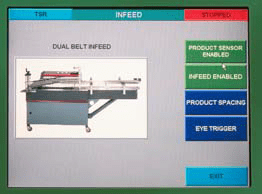

Plug-and-Play Infeed Modules

• Quick - Infeed changeovers in less than 10 minutes

• Value - New infeeds may be purchased separately as needed, giving you long-term flexibility, value and investment protection

• Efficient - Simply choose the infeed module that maximizes your production efficiency

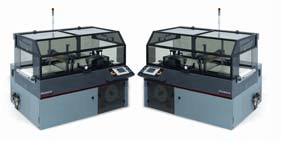

Available in Right– or Left- Hand Configurations

• Versatile - Available right to-left or left-to-right production flow configurations facilitate ease of line integration

• Labor savings – Allows one operator to control two machines simultaneously, maximizing labor resources

Intelligent Control Network

• Intelligent – Automatically identifies attached infeed module and accessories, and configures system accordingly

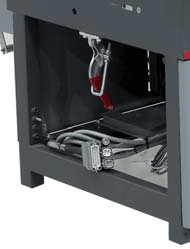

Maintenance-Friendly Design

• Easy access - Light-weight, easy-open seal-area cover, three front-hinged access panels (wrapper, selvage and infeed) and a rear swing-out electrical control cabinet

• Easy maintenance - Quick release conveyor belt rollers, and fault identification and history

Operator-Friendly Design

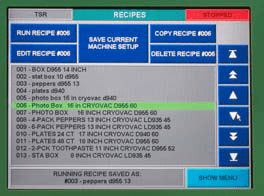

• Effortless - Touch screen provides easy system setup and operation

• Multilingual - Operator interface features English, Spanish and French

• Smart - Enter new package dimensions and the recipe calculator will assist with setup

• Self-diagnostic - Viewable fault log tracks system errors

• Secure - Multilevel security access

Wrapper and Package

Set-up Storage Capability

• Repeatable - Store up to 100 recipes for quick, repeatable changeovers at the touch of a button